The semiconductor industry is essential for meeting growing technological demands. Despite its critical importance, the industry is grappling with significant logistical challenges that disrupt production and innovation. Why the semiconductor industry faces logistical issues has become a pressing question for entrepreneurs looking to enter or expand in this space. Let’s explore the root causes and possible solutions.

Supply Chain Disruptions and Global Dependencies

Semiconductor manufacturing relies heavily on an intricate global supply chain. Different parts of a single chip may come from multiple continents before assembly is complete. This high level of interdependency leaves the industry vulnerable. For instance, geopolitical tensions, trade wars, or even a natural disaster in one region can derail production timelines.

Entrepreneurs entering this market must factor in the risks that come with relying on a far-reaching supply chain. Building relationships with multiple suppliers and exploring localized production options can help small manufacturing businesses mitigate these disruptions.

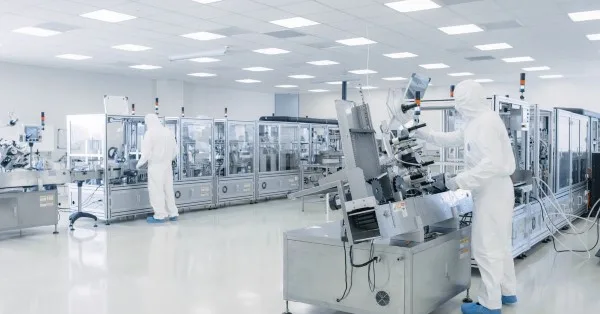

The Growing Complexity of Manufacturing Processes

Producing semiconductors is an exceptionally detailed and technology-driven process. Advanced chips now have billions of transistors packed into a space smaller than a fingernail. Each step demands specialized equipment, skilled engineers, and strict quality control. Any hiccup during these processes can cascade into longer production delays.

Navigating supply chain challenges with advanced packaging solutions that streamline the delivery of critical components has become increasingly essential. For entrepreneurs, investing in innovative technologies and skilled labor is key to overcoming these hurdles.

Shortages of Essential Raw Materials

Modern semiconductors often depend on rare materials like gallium and cobalt. When demand for these resources outpaces supply, prices skyrocket, and delays are inevitable. Securing a steady supply of these materials requires strategic planning and long-term supplier partnerships.

Entrepreneurs must also explore alternative materials or recycling methods to reduce dependency on scarce resources. Investing in material innovation could both cut costs and sidestep potential shortages.

Demand Surges and Market Volatility

Consumer demand for products like electric vehicles, 5G technology, and IoT devices is skyrocketing. While this creates growth opportunities, it also pushes semiconductor demand beyond what the current manufacturing capacity can handle. Rapid surges in demand overwhelm production facilities, leading to backlogs.

Meanwhile, inconsistent supply exaggerates the problem, forcing manufacturers to prioritize one market segment over another. For entrepreneurs, staying adaptable and forecasting trends is vital. Aligning production capacity with demand patterns can reduce market stress and improve profitability.

Conclusion

Logistical crises in the semiconductor industry are not going away any time soon. By exploring issues like global dependencies, manufacturing complexity, material shortages, and volatile demand, we can get closer to understanding why the semiconductor industry faces logistical issues. Entrepreneurs in this field must adopt forward-thinking strategies, from diversifying supply chains to investing in new technologies. Success lies in actively addressing these challenges and seizing opportunities to fortify operations for a more resilient future.